???????????????????

????????????????????????????????????

?????????????????????????????????????????????????

??????????????????????????????

????????????????????

????????????????????????????????

??????????????????

???????????????????

???????????????

???????????????

???????????????????????????????????

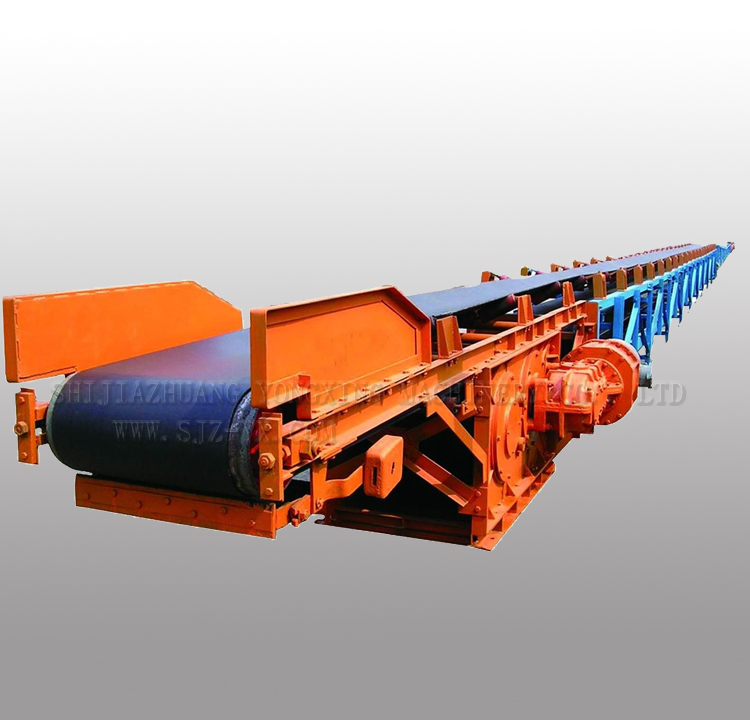

Belt conveyor

DT Ⅱ fixed belt conveyor is a general series of products, which can be widely used in metallurgy, mining, coal, port, power station, building materials, chemical industry, light industry, petroleum and other industries. Single or multi unit synthetic conveying system is used to transport materials. It can transport various bulk materials and finished articles with a loose density of 500-2500kg / m3.

DT Ⅱ fixed belt conveyor

(1) DT Ⅱ fixed belt conveyor is a general series of products, which can be widely used in metallurgy, mining, coal, port, power station, building materials, chemical industry, light industry, petroleum and other industries. Single or multi unit synthetic conveying system is used to transport materials. It can transport various bulk materials and finished articles with a loose density of 500-2500kg / m3.

(2) The suitable working environment temperature of DT Ⅱ fixed belt conveyor is - 25 ~ 40 ℃. For the belt conveyor working in the special environment, if it is required to have the conditions of heat resistance, cold resistance, waterproof, anticorrosion, explosion-proof, flame-retardant, etc., corresponding protective measures shall be adopted separately.

(3) DT Ⅱ fixed belt conveyor is designed according to the component series. According to the requirements of conveying technology, the designer can select the type of conveyor according to different terrain and working conditions and combine the whole conveyor. This series of components can meet the requirements of horizontal and inclined conveying, and can also adopt the conveying form of convex arc section, concave arc section and linear section.

(4) The particle size of the material allowed to be conveyed by the conveyor depends on the bandwidth, belt speed, slot angle and inclination angle, as well as the frequency of the occurrence of large materials. The maximum granularity applicable to various bandwidths is recommended in the following table. When transporting hard rock, when the bandwidth is over 1200mm, the grain size should be limited to 350mm, but not increased with the increase of the bandwidth.

Company:Shijiazhuang Yongxing Machinery Co., Ltd

Contact:Mr.wen

Tel:86-311-88219661

Mobile:86-18931860549

E-mail:[email protected]

Address:97 kilometers of HENGJING Road, Luancheng District, Shijiazhuang City, Hebei Province, China

???????????????????

?????????????????????????????????????????????????

??????????????????????????????

????????????????????

????????????????????????????????

??????????????????

???????????????????

???????????????

???????????????

???????????????????????????????????